Your are here: SERVICES > WHAT IS LEAN?

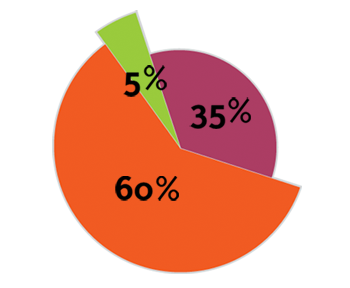

The Lean Enterprise Research Centre (LERC, 2004) at Cardiff Business School highlighted that for most production operations the elimination of waste represents a huge potential in terms of manufacturing improvements.

|

What kind of results should you expect from a Lean implementation?

• Defects reduced by 20% |

Lean is a manufacturing strategy and a way of doing business with a set of tools that seek to conserve and harness all available resources to produce maximum value for the customer.

Lean has a strong bias for ACTION. It builds momentum in incremental steps and continuous improvements. The three main goals of Lean are to:

![]() Identify value

Identify value

![]() Eliminate waste

Eliminate waste

![]() Generate flow

Generate flow

It is important to emphasize that Lean is not just a cost reduction effort, or changing a few steps in our manufacturing process. Lean is about the complete change of business—how the supply chain operates, how the directors direct, how the managers manage, and how employees go about their daily work. Everything.